After a century of domination by the heavyweights of the building industry, we are now living in an age of environmental awareness, and thus the use of timber in design and construction is gaining more momentum than ever before. Design Director Rob Partridge, Director Ricardo Candel and Associate Ed Durie detail the strides made in timber design and what more can still be done.

Timber is here to stay, and whilst internationally there is overwhelming support, there are also many ‘traditional hurdles’ we need to consistently navigate to ensure continuity of this material breakthrough.

The only way to achieve this drive is to adopt a culture of first principle design and research, which needs to embrace not only front-end design and thinking, but be woven into all aspects of procurement, fabrication, construction, and certification.

At AKT II this approach is second nature and aligns with our philosophy of design curiosity, rigorous interrogation, and delivery of innovative industry firsts. Thus, below we wanted to share a sample of these timber initiatives old and new.

Fuelled by the housing market’s appetite for prefabrication, the use of panelised engineered timber products has been on the rise for the last two decades. Our cross-laminated timber (CLT) extension to Hunsett Mill in 2009 with ACME was part of a group of early CLT prototypes in the UK which instilled new confidence within the industry, sparking the timber revolution we now see unfolding across Europe and the US.

This worldwide traction has not only resulted in an unprecedented increase in timber construction over the last decade but has also captured the imagination of the engineering fraternity, with popular headlines capturing the latest utopian ‘wooden towers’.

It is, however, important to note that our obsession with the race to build tall timber may be distracting. High-rise timber is a genuine feat of engineering and the research from such projects is invaluable, but is the ‘prize’ being prioritised over the clarity of design? In 2012, we collaborated with C.F. Møller and DinellJohansson’s HSB Västerbroplan, where the competition winning aspiration was to evolve the Swedish timber prefab model of the 1960s into contemporary high-rise living. Even today, this project is held up as a beacon to timber high-rise; the idea here was not just about engineering or construction, but a lifestyle proposition linked to new ways of thinking in terms of sustainable ecology.

In transferring this model across a range of scales and tenures we have been able to begin to examine how exposed timber in living environments can affect both the psychological and physiological wellbeing of its inhabitants. Our latest collaboration with ACME; Bumpers Oast in rural Kent alongside Haus Gables in the US, illustrates the versatility of timber in creating sustainable and enjoyable homes.

At the other end of the spectrum, we collaborated with architects OFIS in 2017 to explore the concept of ‘permanency’ and whether temporary and demountable timber micro-units could help solve the growing housing challenges of dense urban areas. The resulting Living Unit was erected in a couple of hours within the courtyard of our home at the White Collar Factory and helped illustrate the simplicity of a mobile solution to relieve pressure on our housing market.

Within the circularity of sustainable design, the reuse of existing assets also becomes fundamental. Timber framing is inherently useful here given its reduced density making it not only easier to handle but also able to maximise extension volume over the heavier alternatives.

With the case of a new project in London, AKT II have been tasked alongside architects KPF with transforming an existing factory into retail and office space, plus adding an additional five storeys of residential units on top of the existing long-span RC frame. Once extensive research and analysis had been conducted into the existing structure to understand and identify residual capacity, AKT II explored how best to achieve the maximum floor area for the additional residential storeys. A CLT frame option proved to be optimal in minimising works to the existing structure, as well as providing additional benefits to cost, programme, and sustainability by allowing for extensive off-site fabrication thus reducing on-site activities.

Of course, in the UK our industry is continuing to grapple with government policy fuelling a traditional public perception around the challenges of using timber. However, this continues to propel us to accelerate research into material science and fire engineering which in turn is generating new typologies of hybrid systems, which may be appropriate on developments.

As illustrated above, the wellbeing benefits of timber as a proxy to nature are nothing new, and the philosophy of designing with timber has always been based on these metaphysical benefits, as well as the material’s mechanical properties. The fact timber can be ‘worked’, cut or shaped and simply connected by screws or nails, characterises its position as one of the most versatile construction materials. Therefore, an expression of the honesty of this craft can produce some of the most beautiful and inspiring designs in the world, from ancient eastern architecture to contemporary shells.

Our collaboration with Foster + Partners has seen two distinct approaches to expressed timber structures. Firstly, the Knowledge Centre in the Masdar Institute of Science and Technology, Abu Dhabi boasts a balanced cantilever roof which expresses the hierarchy of timber elements below a stress skin envelope. In contrast, the vortex in Bloomberg’s European HQ comprises three twisted timber shells, reciprocally supporting each other providing a unique and immersive entrance volume.

Another example is predicated on the scalable nature of timber, where the simple repetition of prefabricated components can produce large continuous shells. Here at Oslo Airport a 300 m curved roof is formed using twinned curved glulam beams to span 30 m, with prefabricated roof cassette systems spanning 9 m between.

More recently, it is the question of whether timber can ‘perform’ within the open-plan and flexible nature of large floorplates akin to commercial offices, which is driving much of our research. This sector has been used to decades of concrete and steel frames and thus it is imperative that we don’t simply reinvent old systems with a new material; the ideal of a continuous flat soffit akin to a homogenous material like concrete, or holes through downstand beams as in the case of castellated steels.

If the full potential of timber is going to be exploited, then the framing and connection choices should follow the rules defined by the simplicity of timber. Thus, our search for environmentally appropriate design needs to strike a fine balance between maximising the efficiency and life of a building with sustainable material use and construction. The result of such evaluation presents opportunities to combine different materials creating new hybrid systems where the behaviour of timber is essentially enhanced.

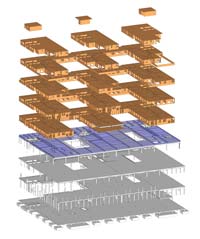

One such example is a project where a composite system of timber and steel is most suitable. The global system provides future flexibility which is achieved via a hierarchical structure of permanent master floors separated by hanging intermediate floors of steel and timber. As with many of our innovative designs, these hybrids are not covered by codes or design guides and need to be approached through first-principle testing. In the case of this example, a full-scale prototype was constructed, and a rigorous suite of testing carried out to inform the dynamic performance of this bespoke system. The data retrieved has been invaluable which we can now use to continue to refine timber engineering – another obvious sustainable goal.

A recent variation to material hybrids is to begin to combine different timber species together – using the benefit of hardwoods in small quantities to effectively reinforce softwood. This was our approach in Maggie’s Yorkshire with Heatherwick Studio where LVL inserts have been used to reinforce the areas of high stress in slender cantilevering glulam ribs.

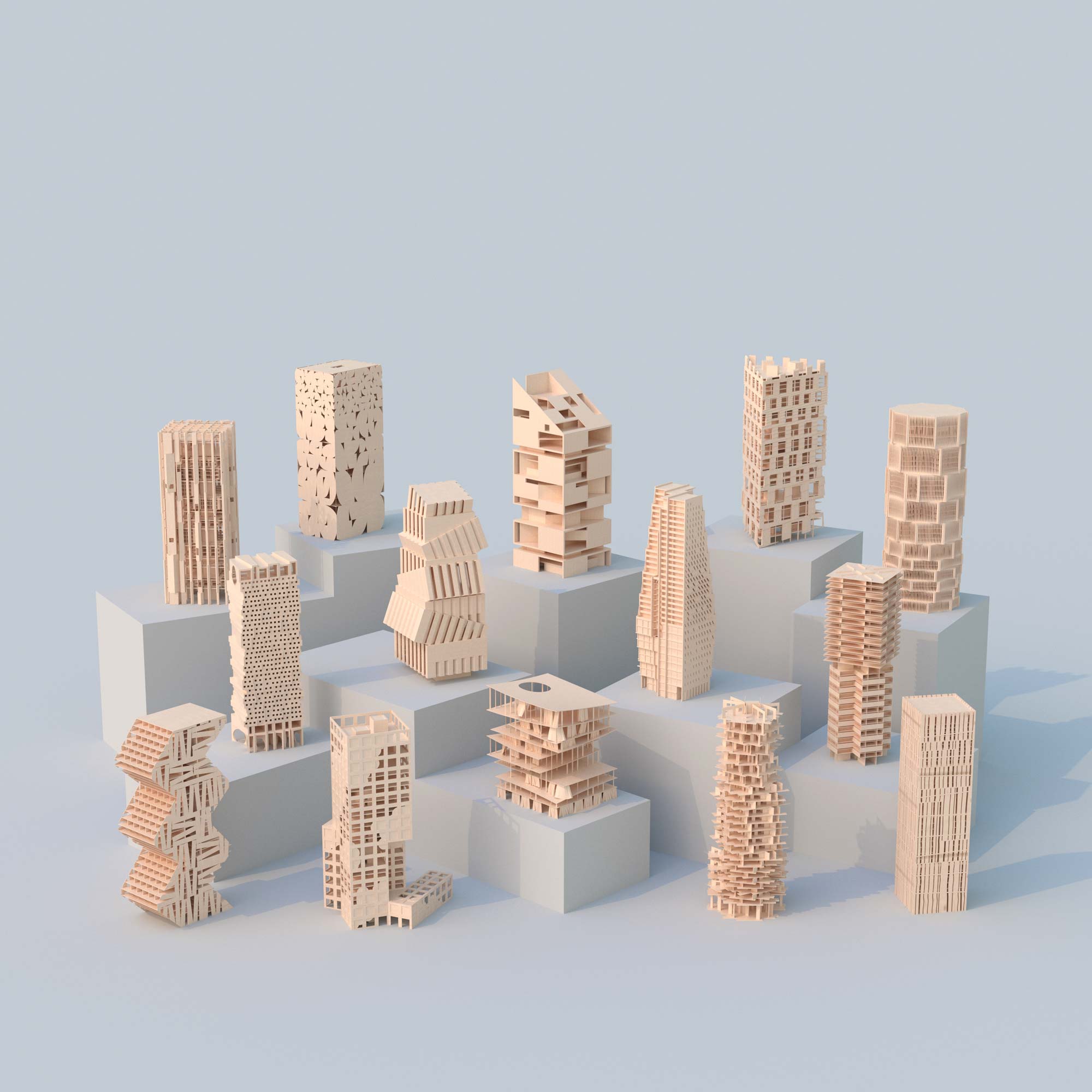

Our commitment to research in practice works hand in hand with theoretical learning, and thus AKT II has always taken an active role in academia. A recent example of this integration was a joint option studio at GSD Harvard with Hanif Kara and Jennifer Bonner, assisted by Nelson Byun, titled Mass Timber and the Scandinavian Effect. The aim of the studio was to speculate on the possibilities and patterns emerging from Scandinavian countries and marry the basics of using ‘CLT Blanks’ with an appreciation of the aesthetics of wood, into a low rise and tower typology.

With future generations motivated by the climate emergency and inspired by advances in material science and digital technology, the age of timber design engineering is here to stay.