Unitised façade systems allow a rapid, high-quality install with relative ease, thus saving time and money – a win in anyone’s books. These systems also make it extremely difficult to replace any of the units’ constituent components.

In this latest article within our ongoing AKT II Envelopes series, our design engineer Rob Jones explores existing considerations of façade disassembly and reuse, and speculates on how façade design approaches may evolve in the future.

For decades, the drive to make façades more cost- and programme-efficient, together with the need to ensure factory precision throughout the build, has led to the development of the unitised façade. Most of today’s office façade systems are ‘unitised’; they are prefabricated as large envelope units which integrate several components and functions and are simply craned and fixed into position to enclose the building.

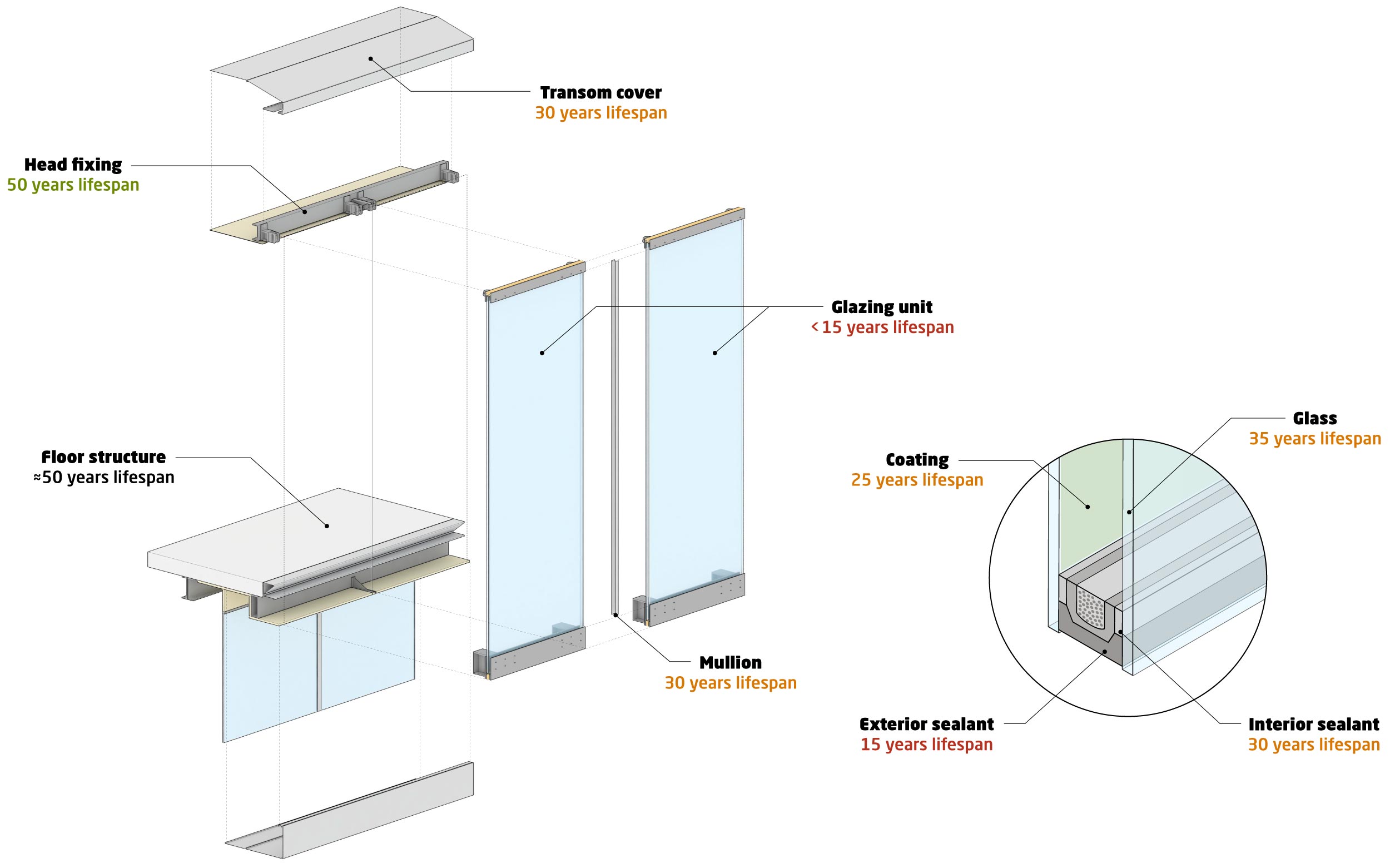

Once on site, this method is fast to build, and brings with it a high-quality ‘factory conditions’ construction. But this ubiquitously adopted response results in large-scale elements and systems that are inherently difficult to take apart. And this means that any failure of a small part within the system can lead to many other, perfectly functioning parts being needlessly disposed of, much earlier than truly should be necessary.

So we propose a question. Is this approach still appropriate, in a world where optimising embodied carbon and extending structural lifespan are increasingly important? Or are there, perhaps, alternative ways forward?

Recent industry discourse into the ease of taking apart a typical façade unit has demonstrated that the unitised systems are fundamentally incompatible with the idea of being simply disassembled. Many of the in-unit connections use adhesives or other bonding agents, which are difficult to remove without causing damage to the constituent components.

Consequently, a single component failing or reaching the end of its designed life, within the unitised element, then typically triggers the requirement for replacing its entire unit. These days, the precept of a throwaway society – the ‘let’s just replace the whole thing’ response that was once commonplace across the industry – has become less acceptable, amidst society’s increasing focus on sustainable design, responsible resource use, and waste avoidance. Many other products are being redesigned accordingly.

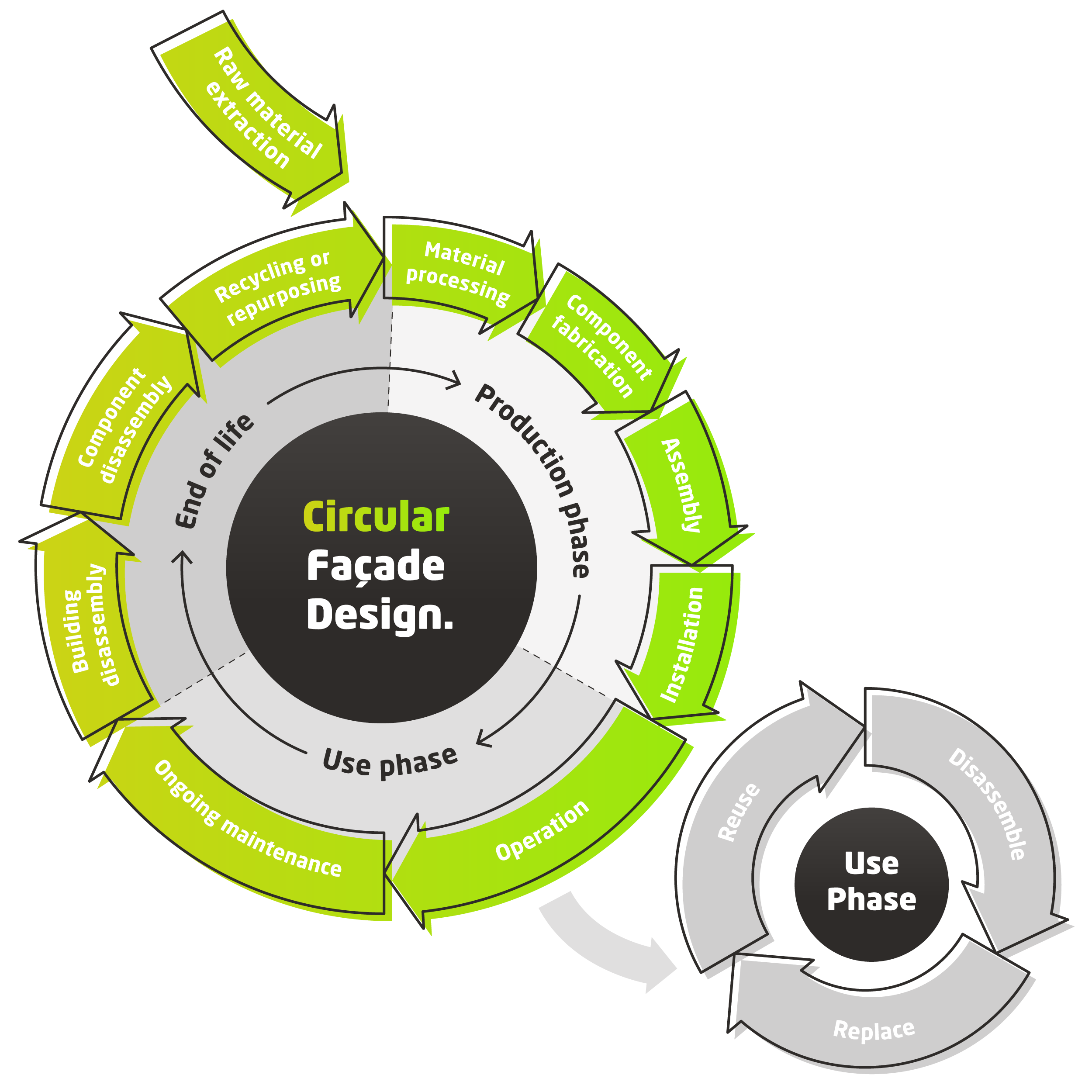

Construction technologies that consider ‘design for disassembly’ principles will help to enable this final end-of-life dismantling of façades, and may be the decisive factor in making façades recyclable and reusable. In all of a building’s elements for which the designed life or expected utility timeframe is short, such design-for-disassembly must now become a clear imperative.

Manufacture, assembly and disassembly must all be considered within the design stages, to support the recycling of circular materials and components. To successfully plan and design for future renovations, adaptations and recycling processes, we must also understand the individual components’ lifespans. Prefabricated and modular solutions can reduce initial capital cost, on-site time and construction waste, and can potentially optimise the building’s operational energy and carbon. But these positives must be weighed up alongside the less-positive design qualities such as the use of glues and resins that make future disassembly or renovation problematic. Rationalising any free-form geometries, panel repetitions and connection details will simplify production, and will further reduce cost.

Currently, façades are constructed without considering the possibility that, at some point in the future, a significant number of panels could potentially require contemporaneous refurbishment or replacement in a manner that may extend the entire envelope’s life. For many buildings, the building-management units (BMUs; the manned gondolas that descend on wires down the sides of many tall buildings) are able to facilitate the replacement of an individual panel should the panel fail. But this doesn’t offer a cost- or time-efficient mode of replacement for multiple panels, within any given timeframe.

As such, replacing large numbers of façade panels typically requires extensive temporary works and/or cranage, which poses little overall cost or programme benefit when compared with simply installing an entirely new system across the entire envelope. Furthermore, there’s a risk that any replacement panels will fail to visually match with the otherwise uniform appearance of an existing, weathered façade – adding a further, aesthetic dimension to the problem.

Individual manufacturers incorporate their own unique detailing within the façade’s technical design and its connective interface with the structure; any ‘inter-system compatibility’ between the original and new façade units is potentially troublesome. This can even be the case between units from the same manufacturer if systems have evolved over time. This adds another level of complexity to any attempted re-use of the façade’s existing parts when the overall system reaches the end of its life.

In summary: there are many challenges that designers and manufacturers must resolve in order to avoid the outcome of wholesale replacement being triggered when a relatively small number of components or units fail. In recent times, the useful lifespan of a façade has tended to be terminated prematurely by the failure of individual components which, due to current conventions of façade-system design, then trigger the replacement of entire envelopes. Most building designs consequently are not currently conducive to easy façade refurbishment.

To move into a modern world, wherein a throwaway mindset is simply unacceptable, we must look to exploit the existing opportunities that may potentially greatly extend a typical envelope’s lifecycle:

Currently, there isn’t a driving force from clients, nor from regulation, to encourage this evolution of façade lifespan. If clients and occupiers could moreover make this circular economy a greater driver within their own commercial decisions, then perhaps such design opportunities could be considered more widely.

Within the current financial model, the initial construction costs are viewed separately to the operation and maintenance costs, with the latter two often simply passed on to the occupiers and owners. Façade contractors hence lack any incentive to invest in façade components’ reusability because the up-front capital costs, within this existing model, are not recovered.

The implicit paradigm shift that’s required within the financial model may seem unfeasible. Yet, many industries have already taken the leap.

It might be time for the façade industry, now, to take the plunge.

All of these insights and ideas are already being explored by AKT II Façades, as part of our sustainable delivery of high-performance design.

To learn more about the value that AKT II Façades brings to projects over the world, get in touch to see how we can help.

AKT II Façade Engineering 25

25 Whitworth

Whitworth White City

White City  NXQ

NXQ Luton Power Court

Luton Power Court St Pancras

St Pancras The

The Apex

Apex