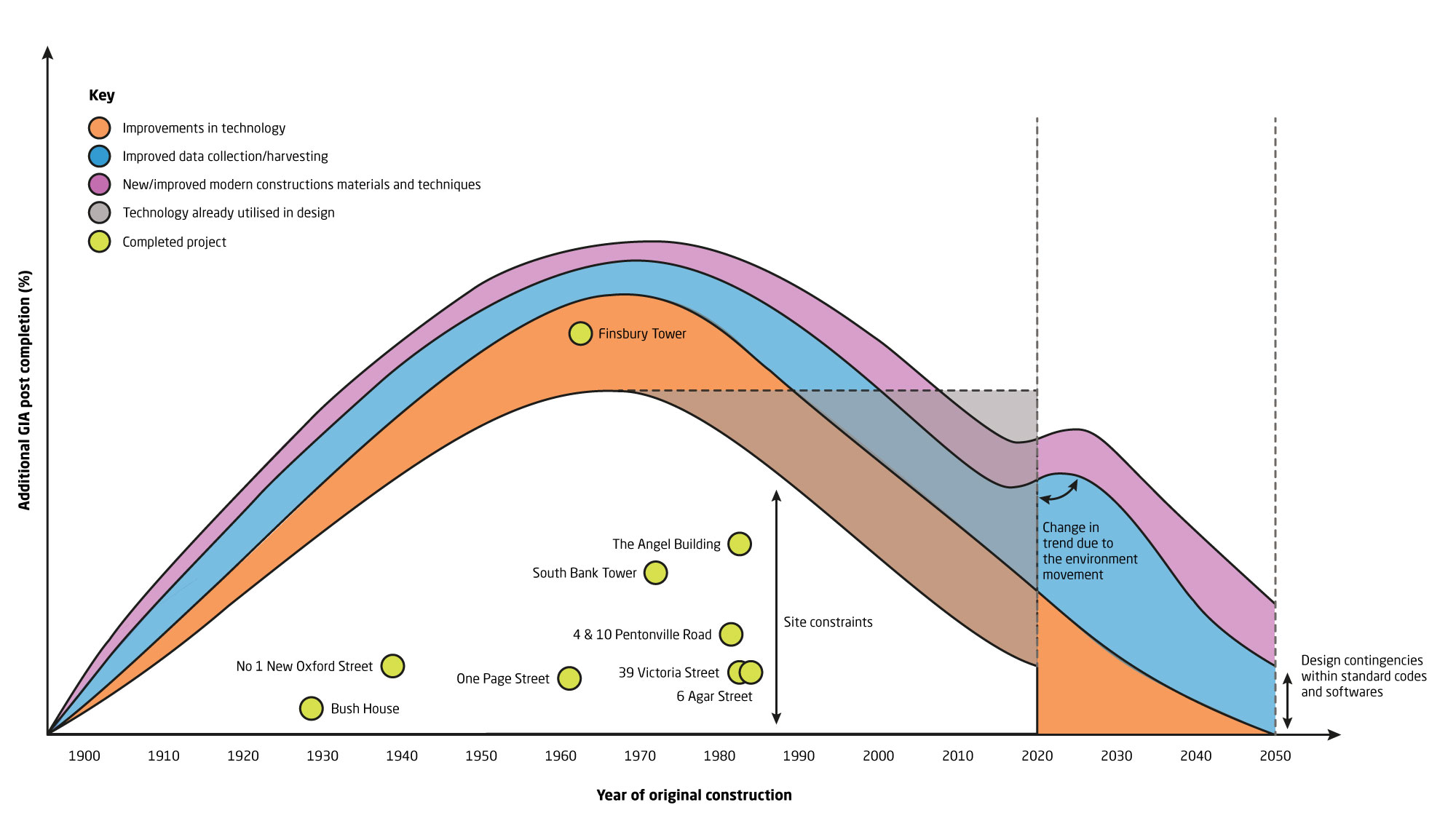

Structural engineers have been refurbishing and repurposing buildings for generations. As a matter of course in our profession, we have to look towards the benefits of reusing existing structures as much as possible, becoming experts at breathing new life into buildings whilst working within their inherent limitations. In this article, we detail how we can continue to improve on reusing existing buildings.

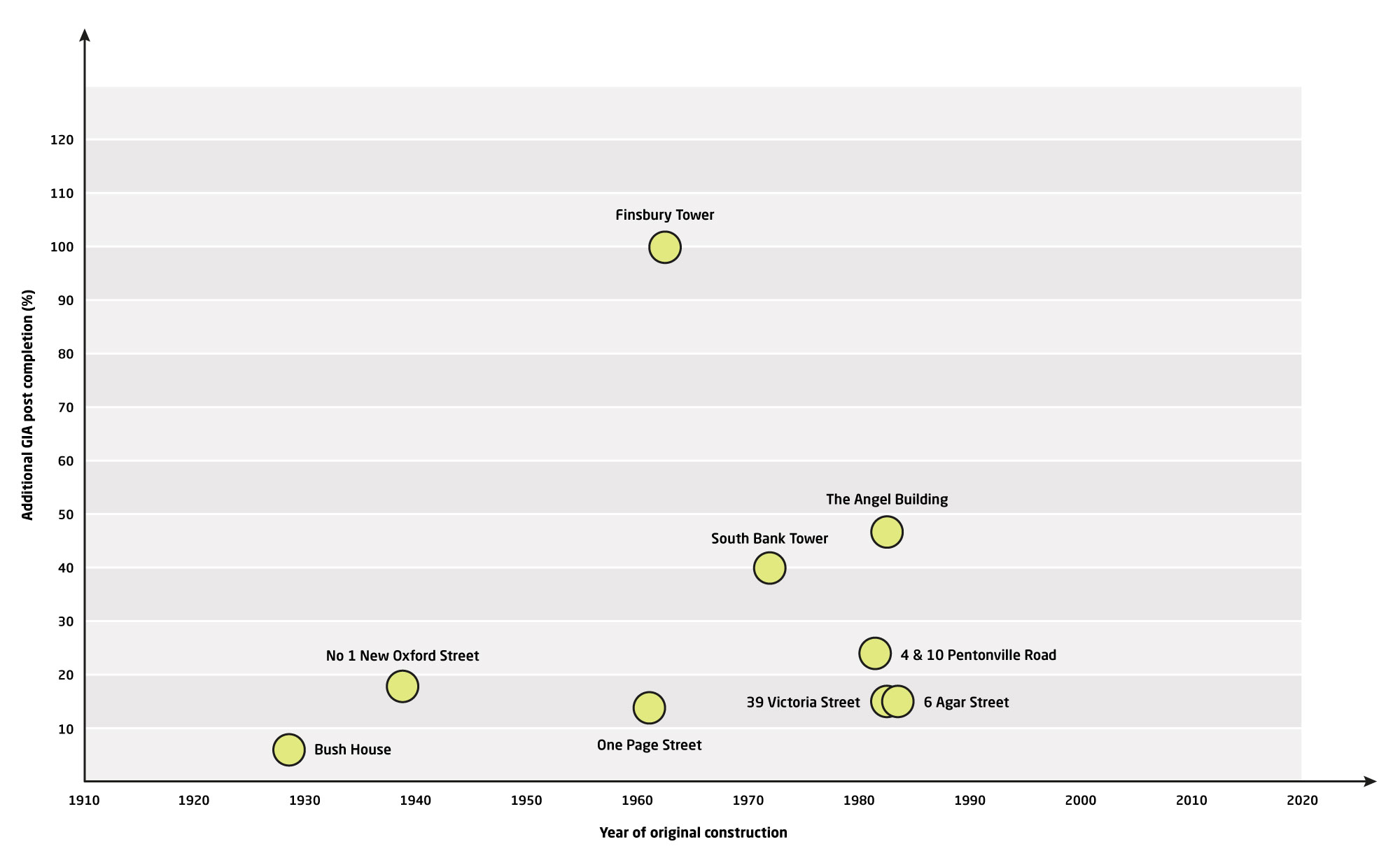

A recent example of this is the recently completed refurbishment of No.1 New Oxford Street. This building was originally constructed in the 1930s and through hard work and good engineering practice, we managed not only to maintain most of its original frame but also to add an additional floor.

This project is one we are rightly proud of as it has both exploited the potential of the frame and the site itself, and is a good benchmark of what engineers have typically achieved over the last two decades working with buildings where we have very limited information on the design and material properties of the fabric.

We are now seeing our approach to the refurbishment of existing buildings is changing. This is not only due to the clear sustainability advantages of reusing what we have, AKT II fully support campaigns such as the Architect’s Journal’s #retrofirst campaign, but also because we have access to solutions releasing more potential than ever before when working with existing structural frames. With better, more expansive information allowing the maximum opportunity of these ‘old’ structures to be unlocked. We believe this shift can be attributed to three independent yet interlinking factors;

1. Building stock

Buildings constructed in the 60s, 70s, and later are fundamentally different from buildings of the early 20th century and often have more robust frames, with less latent defects. Therefore, as engineers, we have the ability to change the entire structural philosophy of these buildings and not be limited to the basic cut and carve of the frame.

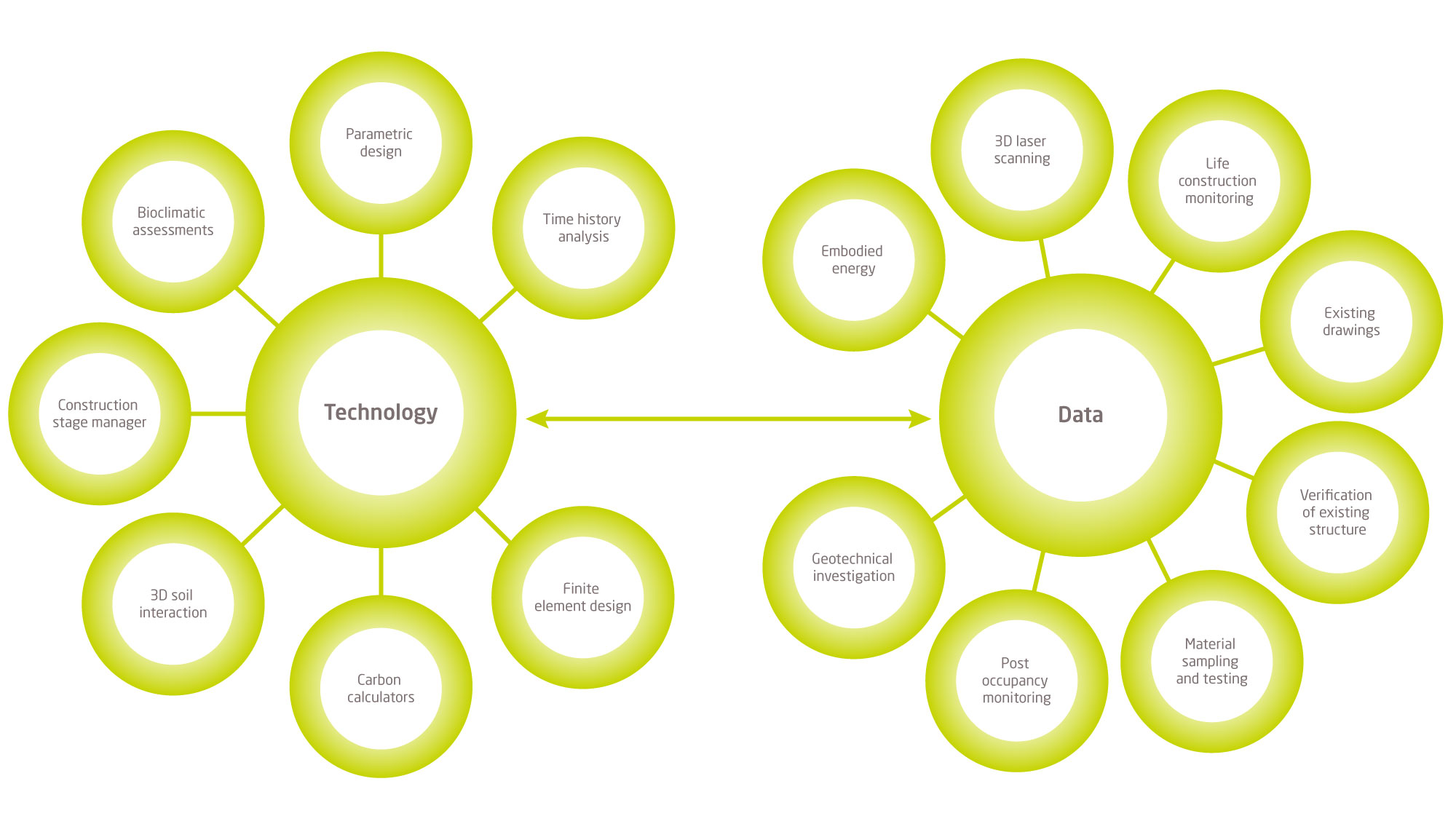

2. Data

We are now reaping the benefit for developers of situations where copies of the original design drawings are accessible and possibly even site records of the construction process. Having this data, supplemented by early upfront insitu material and geotechnical testing provides a huge advantage. This data allows for forensic engineering to take place very early in the design process, controlling project risk, and importantly allowing this pre vacant position (VP) and planning submissions.

3. Tools and technology

The development of new tools and technology has further advanced the ability of engineers over the last 10 years. The unprecedented boom in technology allows us to analyse buildings in a wholly different way to previous generations of engineers. One particular area that has significantly benefited is geotechnical engineering. In the past 5 years, these technological advancements have aided geotechnical and structural engineers to access and unlock latent potential within buildings that the original designers were unaware they had left for our present-day engineers to exploit.

This significant paradigm shift, coupled with hard work, empathetic working, and a passion for the success of the project has led to the recent successes of numerous reuse projects including South Bank Tower, Hylo, and 100 Liverpool Street.

South Bank Tower (with KPF for CIT Group, completed in 2016) was a hugely successful project for both our practice and for the case of retrofit first. The fundamental element of this project was the addition of 11 storeys to the 1970s, 30-storey tower. Whilst the original designers on this project had designed South Bank Tower in the best way possible at the time, with the tools available now we found that the addition of 11 extra storeys was still feasible and achievable.

We used the data available to us, in the form of existing drawings, to analysis the existing building and get into the mindset of the original engineer, cross-checking the codes, materials, and tools they would have used at the time. We then reanalysed the building making use of modern analytical tools to identify where the building had residual capacity.

In this building, it became apparent that the core was robust but susceptible to overturning, and the columns were limited by an architectural inward step. Therefore, to resolve both issues, and still extend the building, we drew load into the core and away from the columns with large concrete wing walls and macalloy cables.

This prestressing of the existing core combined with a CFD wind analysis allowed us not only to add the additional storeys on top but actually allowed us to weaken the original central core. The core modifications allow the tower to be converted from an office to high-end residential apartments.

The extension of South Bank Tower (SBT) could be seen as a special case or a ‘one-off’ – and whilst they are different structures requiring different designs, the results on the Hylo project (formerly Finsbury Tower, with Horden Cherry Lee Architects for CIT Group, on-site) were not dissimilar. Applying some of the lessons learn and principles used on SBT we were able to extend Finsbury Tower by an additional 13 storeys, taking the tower from 79 metres to 124 metres high.

We worked closely with architects Horden Cherry Lee at a very early stage, and we were able to identify where the residual capacity was and what the structure’s limits were. The existing core was not fit for purpose. Not only was it in the wrong location but it couldn’t adequately serve a larger building. As such we needed to replace it, however, the existing frame and foundations were all suitable for reuse.

Geotechnical engineering is no longer the ‘mysterious’ practice it once was, and the advancements in modelling software allowed us to reuse all the existing foundations below the new core and place a new 29-storey core adjacent to an existing 16-storey frame. We created a detailed model of the existing frame, as we did on SBT, and modelled every stage of construction so that we could understand how concrete would behave from the 1960s until the 2050s. This allowed us to understand how force would distribute and change over time. This detailed analysis allowed us to ‘fix’ any problems in the existing structure before they happened, giving new life to the building.

100 Liverpool Street (with Hopkins Architects for British Land, on-site) was built in the 1990s and shows the potential of what we still can find in even our youngest buildings. This project however was not only defined by the potential of reusing within the existing steel frame and not even by its close proximity to national rail and TFL underground lines but the limitation of having sitting tenants within the basement. These limits meant we were unable to change the foundations and had to rely on the existing frames. Despite all of these constraints, we were still able to increase the net internal area by 30 %. This was achieved by understanding the existing structure and having the project team analyse record drawing, to carry out detailed studies of the existing frame. These studies were carried out at an early stage and shaped the scheme. We carried out strategic strengthening work to realise the potential within the frame with over 6,000 beams redesigned to facilitate the final design.

We believe it is imperative that the projects discussed above become a new benchmark for what is considered a retrofit success. As an industry we cannot rest on these successes rather we must continue to develop our retrofitting skills alongside looking into existing building stock, data and tools, and technology.

Firstly, we need to identify which elements of our existing building stock should be used and how they should be used. This needs to be a cross-industry discussion where value is weighed against not only cost and program, but also against carbon expenditure.

Secondly, we must not only protect our existing data but strive to actively collect even more. Data-driven design means the active of collection data is crucial as it will enable the next generation of engineers to go beyond what we can do now. We at AKT II are already doing this with live monitoring during construction on the Finsbury Tower project and post occupational occupancy monitoring at the White Collar Factory and acceleration monitoring of One Park Drive tower.

Third and finally, we need to continue to connect with academic institution and integrate with software developers to ensure that those of us ‘at the coal face’ of the industry drive the technology advances needed to further push the boundaries of reusing and continue to improve what is possible for our existing buildings.