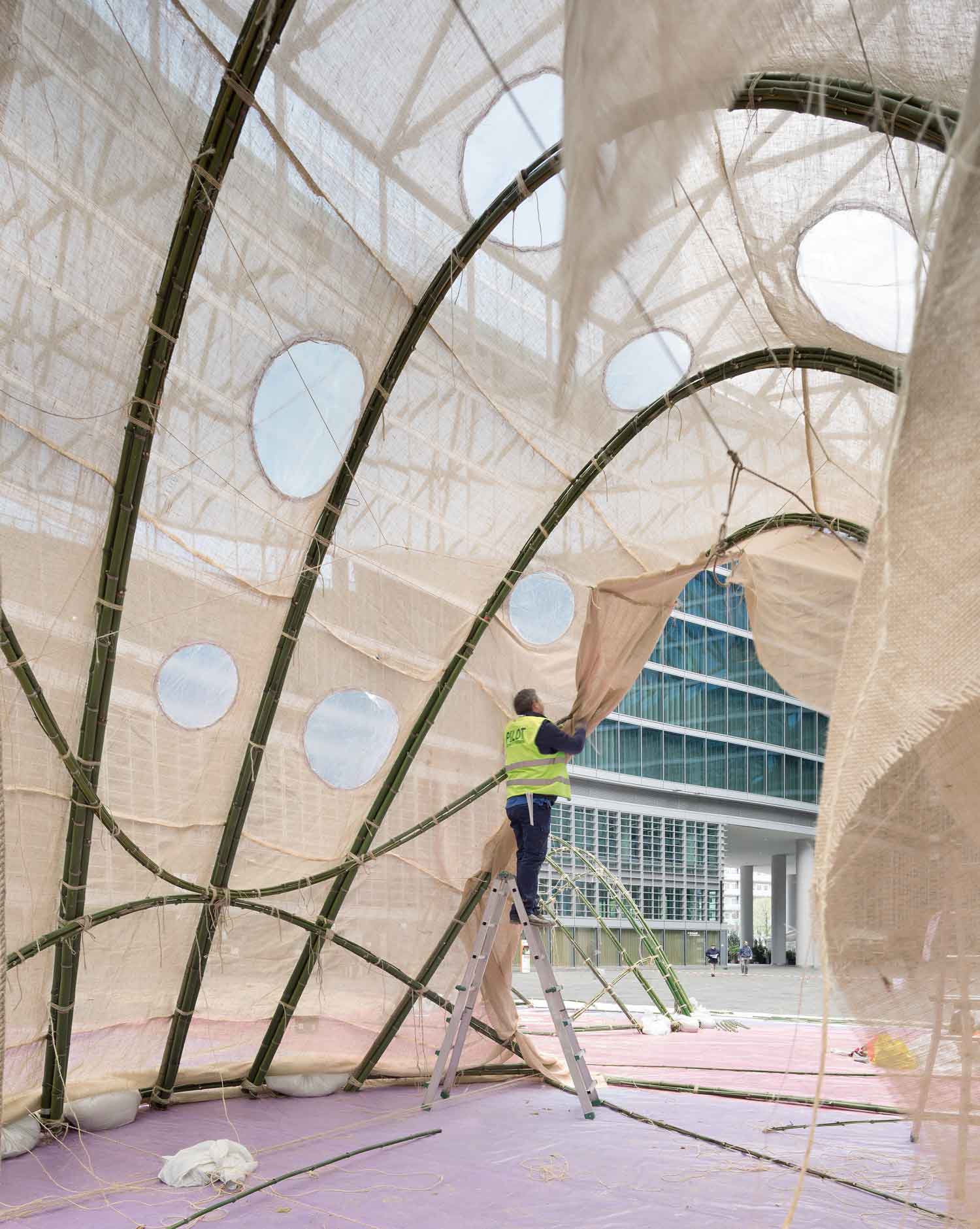

During 2019 Milan design week, MuDD architects collaborated with Canya Viva, Summum Engineering and AKT II to build ‘Terramia’ - housing prototypes using a combination of drone spraying, drone blowing, and drone lifting. Realised in just five days in Palazzo Regione Lombardia, the team utilised local raw materials, such as mud and bamboo, to form the earthen shell. The project aims to showcase how the prototype could be potentially used for low budget or humanitarian shelter.

A prototype project built at pavilion scale that explores innovative drone spraying techniques using natural materials

The drone spraying techniques have been developed through the Innochain network by a multi-disciplinary team of architects and engineers, aimed at coating layers of raw mortars onto lightweight formworks without the need for human access. The drone application opens the opportunities of new architectural forms for shotcrete related technologies.

The Terramia pavilions consist of three freeform vault structures ranging from 3.5m to 5.5m high using stressed bamboo arches clad with jute fabric and later drone sprayed with layers of bio mortars.

Our computation research team worked on the initial form-finding, seeking to rationalise and optimise the competition winning forms of the initial designs into geometries that could efficiently carry the applied loading.

Each arch is formed from a bundle of bamboo stems so arranged that the natural taper of the growing stem points towards the arch apex. The natural lower stiffness at the apex then gives rise to a tighter radius here when stressed compared to that lower down the stiffer leg and the parabolic nature of the curve is so formed. Stressing is generated through physically moving the arch bases towards each other and then restraining the bases with ballast or ties.

Further iterations of form by Summum Engineering were influenced by the sourcing of the bamboo. The limited availability steered the number of arches that could be incorporated within each pavilion and this, in turn, reflects on the degree of faceting of the dome surface and the spans of the jute panels.

25

25 'On Weaving'

'On Weaving' The JJ Mack

The JJ Mack The Farmiloe.

The Farmiloe. Pure

Pure  Tabernacle

Tabernacle  2–4 Whitworth

2–4 Whitworth White City

White City  Aloft

Aloft  NXQ

NXQ TTP

TTP Two

Two 'Radiant Lines'

'Radiant Lines' A Brick

A Brick One

One The Stephen A. Schwarzman

The Stephen A. Schwarzman Albert Bridge House.

Albert Bridge House. Edgar's

Edgar's Luton Power Court

Luton Power Court St Pancras

St Pancras Wind Sculpture

Wind Sculpture Sentosa

Sentosa The

The Liverpool

Liverpool Georges Malaika

Georges Malaika Reigate

Reigate Cherry

Cherry Khudi

Khudi Haus

Haus 10 Lewis

10 Lewis